It’s necessary and essential to make wire harness waterproof. If the liquid enter, the wiring system would break down, even raise security risk. We often do the waterproofing test after finishing wire harness design. Here we introduce the waterproofing rating and how to test.

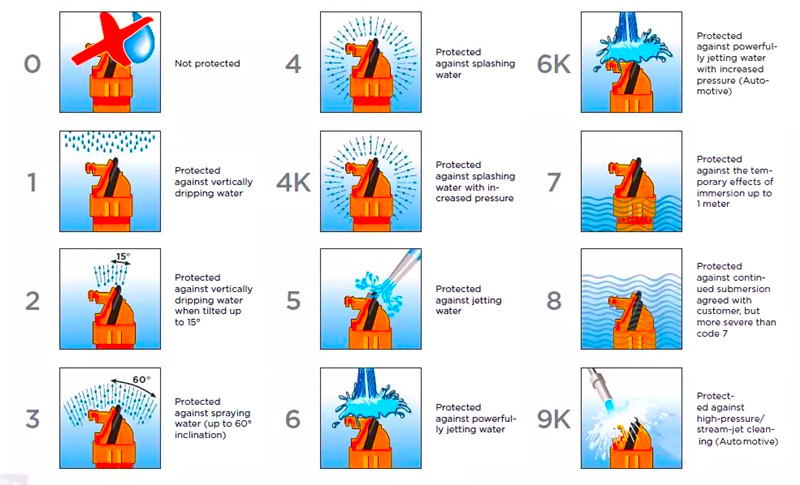

The IP Code, or Ingress Protection Code, IEC standard 60529, sometimes interpreted as International Protection Code, classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. It consists of two digits. The first characteristic numeral means solid particle protection, its range is 0-6 or letter X. The second characteristic numeral means liquid ingress protection, its range is 0-8 or letter X.

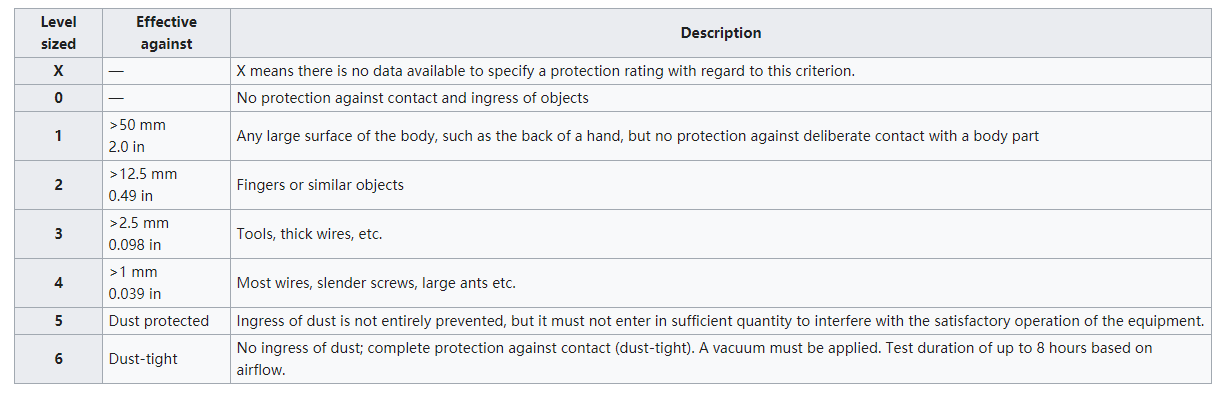

First digit: Solid particle protection

The first digit indicates the level of protection that the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid foreign objects.

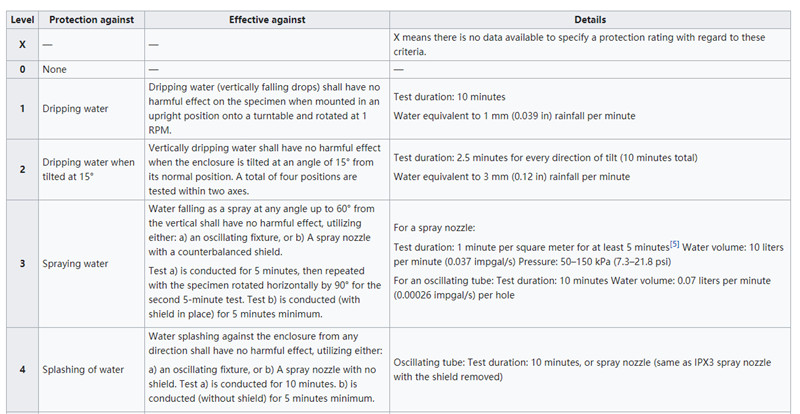

Second digit: Liquid ingress protection

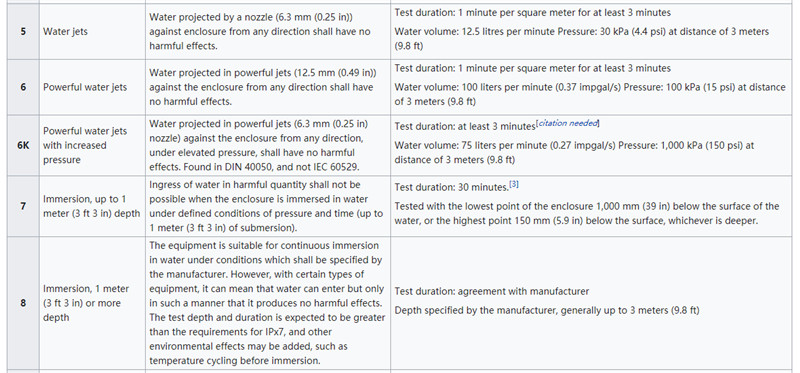

The second digit indicates the level of protection that the enclosure provides against harmful ingress of water. The ratings for water ingress are not cumulative beyond IPX6. A device that is compliant with IPX7, covering immersion in water, need not be compliant with IPX5 or IPX6, covering exposure to water jets. A device that meets both tests is indicated by listing both tests separated by a slash, e.g. IPX5/IPX7.

(All tests with the letter "K" are defined by ISO 20653 (replacing DIN 40050-9) and are not found in IEC 60529, except for IPx9 which is the same as the IP69K water test.)

How to Test?

(1) IP X1

Test Method: Vertically dripping water

Test equipment: dripping water testing device

Test process: set the sample on the rotating device platform with 1r/min, and the distance from sample top to drip outlet is not more than 200mm

Test condition: drip output is 1.0±0.5mm/min

Last time: 10 min

(2) IP X2

Test Method: Vertically dripping water when tilted up to 15°

Test equipment: dripping water testing device

Test process: Tilt one side of sample up to 15°, and the distance from sample top to drip outlet is not more than 200mm。Change the other three side of sample and test again, total 4 times

Test condition: drip output is 3.0±0.5mm/min

Last time: 4 side×2.5min(total 10 min)

(3) IP X3

Test Method: spraying water

Testing process:

A)

Test equipment: Spraying water device with swing tube

Test process: set the device platform directly below the swing tube,and the distance from sample top to drip outlet is not more than 200mm

Test condition: each water output of swing tube is 0.07L/min. Set the sample on the center of the semicircle of the swing tube. The water output on the midpoint of the tube spray the water to the sample at 60°.The tube swings 60°on both sides of the vertical line, total 120°, and each time last 4s

Last time: 10 min

B)

Test equipment: hand-held spraying water device

Test process: the distance from sample top to Sprinkler is 300-500mm

Test condition: water output 10L/min

Last time: accord to the surface area, 1m²/min, at least 5 min

(4) IP X4

Test method: splashing water

A)

Test equipment: Spraying water device with swing tube

Test process: set the device platform directly below the swing tube,and the distance from sample top to drip outlet is not more than 200mm

Test condition: each water output of swing tube is 0.07L/min. Set the sample on the center of the semicircle of the swing tube. The water output on the midpoint of the tube spray the water to the sample at 90°.The tube swings 180°on both sides of the vertical line, total 360°, and each time last 12s

Last time: 10 min

B)

Test equipment: hand-held spraying water device

Test process: the distance from sample top to Sprinkler is 300-500mm

Test condition: water output 10L/min

Last time: accord to the surface area, 1m²/min, at least 5 min

(5) IP X5

Test Method: jetting water

Test equipment:the water output inner diameter of the sprinkler is 6.3mm

Test process: the distance from sample to sprinkler is 2.5m-3.0m, the water output is 12.5L/min

Last time: accord to the surface area, 1m²/min, at least 3 min

(6) IP X6

Test Method: powerful jetting water

Test equipment:the water output inner diameter of the sprinkler is 12.5mm

Test process: the distance from sample to sprinkler is 2.5m-3.0m, the water output is 100L/min

Last time: accord to the surface area, 1m²/min, at least 3 min

(7) IP X7

Test Method: temporary immersion test

Test equipment: immersion device

Test process: the distance of the sample bottom should be at least 1m to water surface and the top should be at least 0.15m

Last time: 30 min

(8) IP X8

Test method: continued submersion test

Test process: accord to the customer’s requirement, but its test intensity will be higher than IP X7

Remark: Many outdoor electronics also require floating ability.

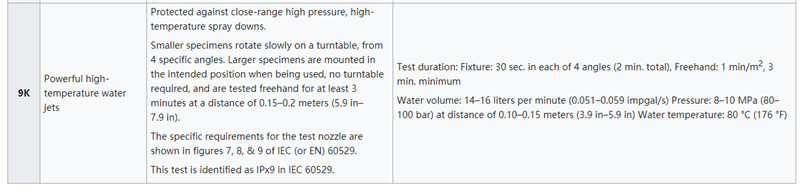

(9) IP X9

Test method: high-pressure stream-jet cleaning(automotive)

Test equipment: the water output inner diameter of the sprinkler is 12.5mm

Test condition: 4 water outlet with 4 different jetting angle(0°,30°,60°,90°)

Test process: rotating platform speed: 5±1 r.p.m, the distance is 100-150mm, each water outlet is 14-16L/min, the water pressure is 8000-10000kPa, the water temperature is 80±5℃.

Last time: each angle 30s, total 120s